|

-

Senior Member

Notice something?

No air filter. At first I tried cutting the stock Honda plastic air filter housing and I was able to get the base piece in place but the filter was hitting the seat belt mounts. Cutting out the seat belts would have been relatively easy and allowed using the Honda air filter but... it would be unprotected against rain and water when washing down. The concave domed top of the filter cap would even funnel the water right into the carb so I'm going to make an adapter and run tubing up to the stock Deere air filter.

In the photo above the black plastic piece in the center is the carburetor intake so I'll have to make a plate and adapt it to round to accept flex tubing, probably aircraft SKEET or SCAT. I wish I had an easy way to show the carburetor inlet area for the Briggs and Honda next to each other. The difference is amazing.

And for those of you with a 550 you'll notice that the bottom part of the seat frame right above the engine and below the seat belt attachment is missing. The frame interfered by about 1/2" with the front cylinder so out came the sawzall and cutoff wheel.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

I'll skip out of order a bit since I found a good way to show the difference in the carburetor inlet area between the Briggs and Honda.

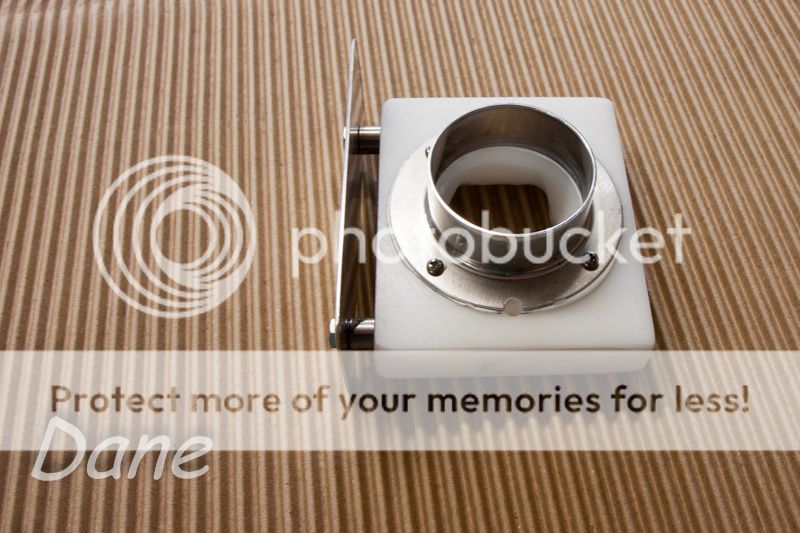

Here is the Briggs carb inlet that comes in the 550. I didn't bother putting a micrometer on it but it's basically an inch! I find it hard to believe that this engine can produce 16 hp breathing in so little air. No wonder it's sensitive to a slightly dirty air filter.

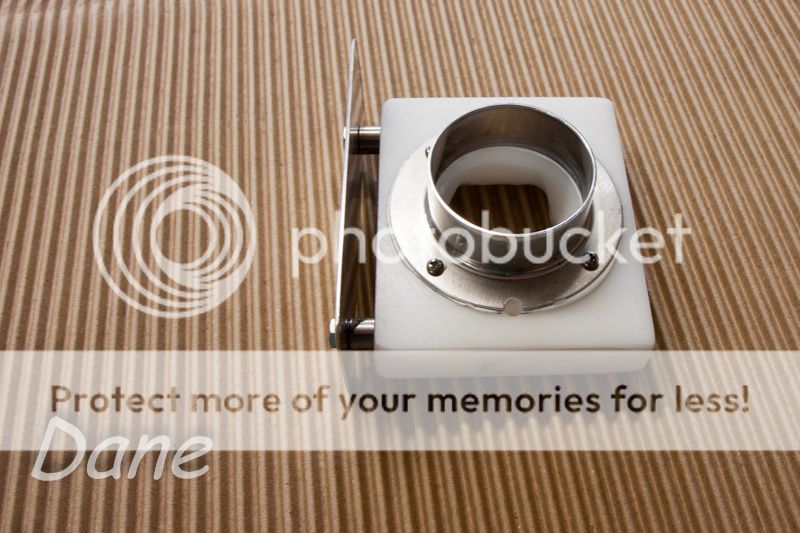

Here is the adapter plate I made for the Honda placed over the Briggs carburetor inlet. Dramatic difference.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

The inlet for the Honda engine is about 2 1/4" by 3 1/2" in a oblong crescent shape (could they make it any more difficult?). The round fitting on the Deere air filter housing is 2 1/2" diameter so I decided to run 2 1/2" tubing between the two. In order to make the transition I took a piece of 1" thick Delrin and after drilling the holes for mounting I used a 2" hole saw to remove the bulk of material from the center. Then I lightly scored the top side with a 2 1/2" circle. On the bottom side I marked out the shape of the Honda's inlet and went crazy with the die grinder with a coarse sanding bit.

There is a opening in the exhaust heat shielding facing the carburetor so I attached a separate shield to protect the plastic. This one is made from aluminum to help keep the weight down since it's supported by the plastic intake which in turn is supported by the carburetor. The round fitting on top is also aluminum and screwed in place with some caulk to insure an air tight seal.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

I ordered both SCAT and SCEET tubing just in case. I knew SCAT would make the bends but was not so sure about SCEET which has a silicone lining which SCAT tubing does not. It has a smoother interior but can't bend around as tight a radius. The SCEET works out perfectly.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

-

-

Senior Member

The difference in power is instantly noticeable. I left the Honda's governor in place so it tops out 500 rpm short of the Briggs which means top end speed is reduced but acceleration is much stronger. You can just tell that there is more power attached to the other end of the gas pedal.

I realized one thing I totally missed. The interlock that prevents driving through the parking brake. My engine install does not have the interlock so I did a test run with the parking brake on. With the Briggs you could feel the brake holding before the interlock kicked in. The new engine just powered through it like it was not there. The only way I knew was the little red light on the dash.

After more driving I've discovered that I have the dreaded can't shift problem. Some of the time the Gator would creep away after coming to a stop and shifting was difficult. So, I tore the bloody thing apart again. Adjusted the idle speed and verified that the primary clutch is releasing as it should. I talked with my Deere Service Manager and he confirmed that I had the old/original belt. To help address the shifting problem in December of 2013 Deere updated their PIP to include replacing the belt with a thinner one. I have one on order but am not totally confident that will resolve the issue. Tomorrow I'll have to spend some time getting technical and checking my clutch alignment and make sure the engine and transmission shafts are parallel. That should be fun.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

The belt currently on my Gator (M161702) is the old, original one used when the 550 first came out. I have the new M172473 belt on order to see if that helps with the shifting problem.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

Congrats on getting it running. You have all the equipment build a brand new unit.

Al

2013 825i - OG&B, Black Alloy Wheels w/ Maxxis Bighorn Tires, Mid range lights (front and rear), Superwinch Terra 45 winch, Koplin Rhino grips, Seizmik mirrors, Silent Benz muffler, rear seat organizer

-

-

Senior Member

After taking the bloody thing apart again the culprit is the primary/drive clutch not releasing fully when the engine returns to idle. It will remain fully open when first starting the engine but after reving up it does not fully open at idle. When I turn the engine off it pops open the last 1/4 to 3/8". I've contacted Team and they are sending a new spring to better adjust the clutch to my engine's rpm's.

In the mean time I've taken my Deere clutch apart and put it's spring in and it's working much better. The problem spring is about 3/4" taller and has wire about .050" thinner than that used in the Deere clutch. With the Deere spring in the clutch it's engaging at about 1'700 rpm and the clutch is fully in high gear about 3'000 rpm. There is no further movement at higher rpm's and it seems to be engaging reliably with the idle speed set to 1'100 rpm.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

-

Senior Member

The engine and clutch continue to work well. Last night I put a GPS in and decided to see what my speeds were. I was cruising along at 25 mph a mile from home and I put my foot down... only to feel the pedal go limp and the engine dropped to idle. Sonofa $%#@ ! Walk home, get a tractor and tow it home.

I had merely cut the end off the Deere throttle cable and put it into the fitting on the Honda which has a screw to clamp down on it. I knew it was not good to have a screw bearing down on a cable but I did it anyhow trying to save some time and avoid one more project. That last bit of throttle really fighting the governor was more than it could take and the cable partially broke and slipped.

I stuck with the existing Deere throttle cable sheath and made a new core. The stock throttle cable has a .050" core which is damn tiny but there is room inside the sheath so I made a new core using 1/16" (.062") cable and instead of relying on the throttle arm's little screw I crimped a ferrule to take the tension.

XUV 550, engine replaced with Honda GX630, MBDiagman tuned primary clutch, all LED lighting, roof mounted Rigid LED lights, split no scratch wind screen, roof, home made rear panel & window and 1/2 doors, Super Winch 4500, set of CST Ancla tires & set of Carlisle All Trail tires

-

|

Reply With Quote

Reply With Quote